PREVENTS CORROSION

Seals underwater metal surfaces on keels, props and more.TWO DURABLE FORMULAS

Surfacing and High-Build epoxy-based formulas for covering fairing or pinholes.DRIES QUICKLY

Lets you recoat in 1-3 hours.EASY TO USE

Simple 1:1 mix ratio, by volume.2-Part Epoxy Primer

2-Part Epoxy Primer

PREVENTS CORROSION

Seals underwater metal surfaces on keels, props and more.TWO DURABLE FORMULAS

Surfacing and High-Build epoxy-based formulas for covering fairing or pinholes.DRIES QUICKLY

Lets you recoat in 1-3 hours.EASY TO USE

Simple 1:1 mix ratio, by volume.Couldn't load pickup availability

One primer, two formulas, multiple uses

Above the waterline, TotalBoat 2-Part Marine Epoxy Primer adheres extremely well to wood, fiberglass, aluminum, and steel. It creates a durable coating that adheres strongly to the surface, seals fairing work, and cures to a flexible film that won’t cause one- and two-part urethane topcoats to lift, crack, or peel. Its advanced polyamide formula improves the gloss of topcoats and helps them last longer so you won’t need to repaint as often.

Below the waterline, apply 2-Part Epoxy Primer to underwater metal parts to keep them corrosion-free so they work better and last longer. Please note: this product is not designed for the prevention and repair of gelcoat blisters and osmotic damage. For a tough, blister-preventing barrier coat under antifouling paint, use TotalBoat TotalProtect Epoxy Barrier Coat Primer. For a protective, watertight barrier to prevent corrosion on aluminum and steel boats, use TotalBoat Aluminum Boat Barrier Coat epoxy primer under antifouling and other 1- and 2-part paints.

For your convenience, TotalBoat 2-Part Marine Epoxy Primer is available in two formulas: Surfacing & High-Build.

- Surfacing Primer is ideal for faired surfaces that are ready for topcoat.

- High Build Primer has a denser, higher-solids formula that’s great for filling small surface imperfections and pinholing prior to topcoat application.

Other 2-part marine epoxy primer systems make you apply the surfacing primer on top of the high build primer so the surface will be smooth enough for topcoats. The nice thing about our epoxy primer system is that you don’t need to use both primers on your project, just the one you need.

2-Part Epoxy Primer Details

- Durable, versatile marine two-part epoxy primer in Surfacing and High Build formulas (not suitable as barrier coats).

- Epoxy primers adhere aggressively to properly prepped fiberglass, wood, steel, and aluminum surfaces.

- Helps improve gloss and longevity when used as a primer under marine one- and two-part urethane topcoats.

- Provides excellent corrosion protection by sealing underwater metal surfaces on keels, shafts, props, and more.

- Surfacing Primer has a high-solids formula that allows rapid buildup of up to 12 mils wet in 3 hours.

- High Build Primer has a denser, higher solids formula that lets you build up to 20 mils wet, total.

- Fast-drying formulas offer faster overcoating times than competitors.

- Easy to sand, once cured.

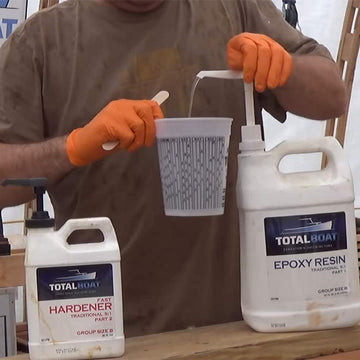

- Simple 1:1 mix ratio

- For use above and below the waterline.

- The High-Build Primer can be used independently and does not need to be overcoated with Surfacing Primer, as with other 2-part marine epoxy systems.

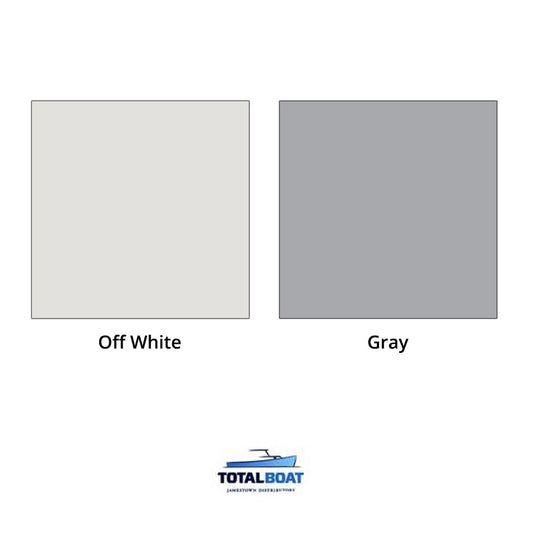

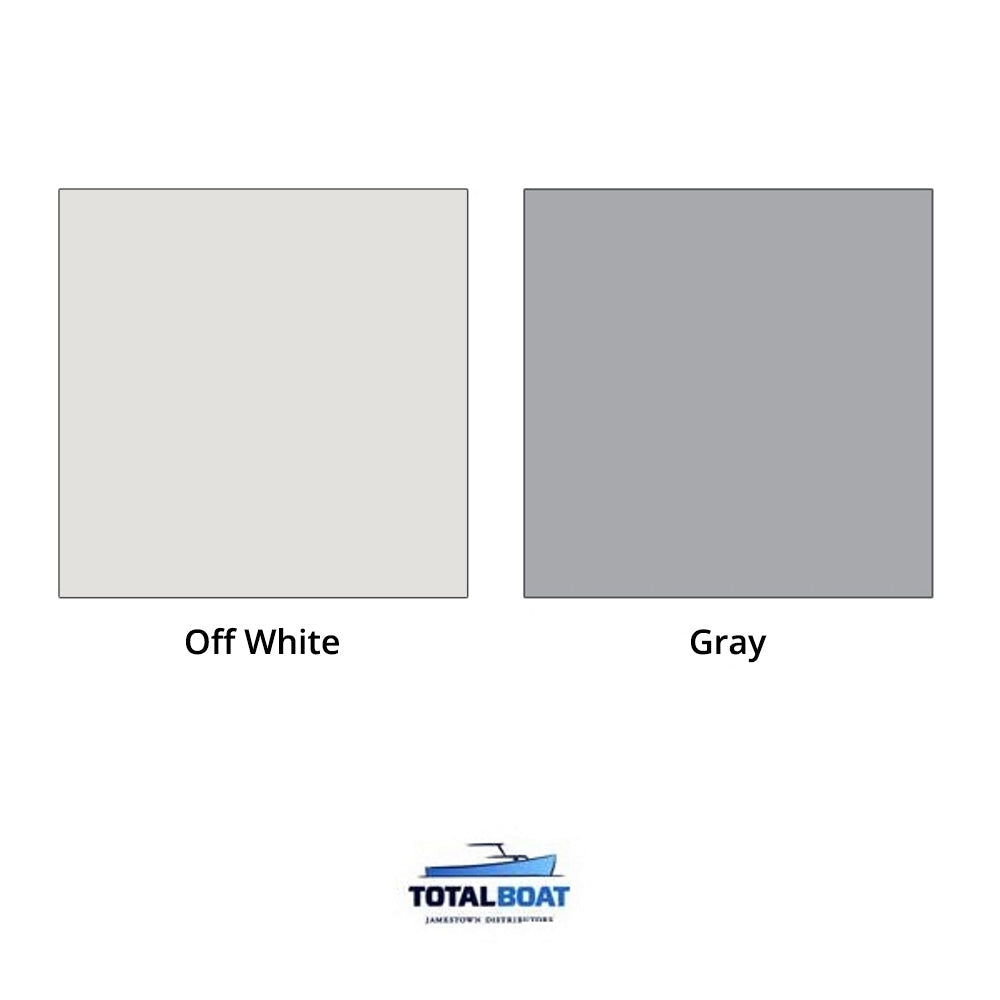

- Surfacing Primer colors/kit sizes: Available in Off White and Gray, in Quart and Gallon kits

- High Build Primer colors/kit sizes: Available in Off White and Gray, in Quart and Gallon kits

- Quart Kit: Includes 1 quart Part A Base and 1 quart Part B Activator

- Gallon Kit: Includes 1 gallon Part A Base and 1 gallon Part B Activator

- Thinner: TotalBoat Epoxy Primer Thinner 200, Quart (sold separately). For thinning, surface prep cleaner, and tool cleanup.

TECHNICAL DATA

- Application Method: Brush, Roll, or Spray (if rolling, use a 1/8" nap, solvent-safe foam roller cover)

- Application Temperature: 45-125ºF

- Number of Coats: 1-3

- Film Thickness (per Coat): 3-4 mils wet

- Pot Life: 8 hours @ 72ºF

- Induction Time: Induct for 30 minutes before reducing or applying

- Dry Time to Recoat: 1-3 hours

- Dry Time to Sand: 4-16 hours (<4 mils dry), 16- 24 hours (>4 mils dry)

- Recommended Finish: Urethane coatings

- Shelf Life: 24 months (minimum)

- Finish: Semi-Gloss

- Colors: Off White or Gray

- Mix Ratio (by Volume): 1:1 (1 part base to 1 part activator)

- Theoretical coverage: Surfacing Primer, 400 sq. ft. per gallon @ 2 mils dry film thickness; High Build Primer, 75-100 sq. ft. per gallon @ 3 mils dry film thickness

- VOC Content (Admixed): Surfacing Primer, <420 g/L; High Build Primer, <350 g/L

- Thinner: TotalBoat Epoxy Primer Thinner 200

- Surface Prep Solvent: TotalBoat Epoxy Primer Thinner 200

- Cleanup Solvent: TotalBoat Epoxy Primer Thinner 200

-

2-Part Epoxy Primer

- Best for:

- Primer type:

- Substrates:

- Above/below waterline:

- Suitable topcoats:

- Application methods:

- Number of coats:

- Thinner:

- Cleanup:

- Coverage:

- Application temperature/RH:

- Units of measure:

- THIS ITEM

-

2-Part Epoxy Primer

- Best for: Sealing filler primers and fairing compounds before applying one-part and two-part urethane topcoats.

- Primer type: Surfacing tie-coat primer or high-build tie-coat primer

- Substrates: Fiberglass, carbon fiber, Kevlar, wood, steel, aluminum, and previously painted surfaces in good condition

- Above/below waterline: Above or below (not a barrier coat primer)

- Suitable topcoats: Urethanes

- Application methods: Brush, Roll, or Spray

- Number of coats: 1-3

- Thinner: TotalBoat Epoxy Primer Thinner 200

- Cleanup: TotalBoat Epoxy Primer Thinner 200

- Coverage: 400 sq ft/gal @ 2 mils dry

- Application temperature/RH: 45ºF to 125ºF

- -

YOU MAY ALSO LIKE

FREQUENTLY ASKED QUESTIONS

-

What are 2-Part Epoxy Primers used for?

The clear primer is ideal to use as a tie-coat before applying high-gloss urethane topcoats. The surfacing primer is great for overcoating, color matching, and improving adhesion, while the high-build primer is best for surface defects. -

Which reducer or thinner should I use with epoxy primers?

Use TotalBoat Thinner 200 as a reducer for the 2-Part Epoxy Primers. -

What is the difference between surfacing primer and high-build primer?

Surfacing primer is ideal for faired surfaces that are ready for topcoat. High-build primer has a denser, higher-solids formula that’s great for filling small surface imperfections and pin-holing prior to topcoat application. The high-build primer can be used independently and does not need to be overcoated with a surfacing primer, as it can be sanded smooth. -

Can I use these primers below the waterline?

Yes. They can be applied both above and below the waterline. Below the waterline, the primers are great for underwater metals. Above the waterline, use on wood, fiberglass, aluminum, and steel. -

Can gelcoat be applied over 2-part primers?

Yes, as long as it’s mixed, cured, and applied properly. -

What is the coverage of TotalBoat epoxy primers?

Surfacing primer will cover approximately 400 sq. ft. per gallon at 2 mils dry film thickness. High build primer will cover approximately 75-100 sq. ft. per gallon at 3 mils dry film thickness. -

How do I apply epoxy primer?

Apply by brush, roll, or spray. If rolling, we recommend using 1/8″ nap, solvent-safe foam roller covers. If spraying, reduce 15-25% with TotalBoat Epoxy Primer Thinner 200 for the desired application and film thickness control. -

What is the ideal temperature range for application?

These primers should be applied at temperatures between 45ºF to 125ºF. -

What is the working time?

The working time for the 2-Part Marine Epoxy Primers is 8 hours at 72ºF. -

How many coats should I apply?

We recommend applying between 1-3 coats of primer. -

When can I apply another coat?

The dry time to recoat is about 1-3 hours. -

How long should I wait before sanding?

A single-coat application can be sanded in 4 hours. For multiple-coat applications, allow 16 hours to cure before sanding. Try not to wait more than 24 hours to sand, especially with only one or two coats, as the primer will get increasingly harder. Use 220-grit or finer sandpaper for the best topcoat appearance.