PREVENTS OSMOTIC BLISTERS

EASY TO APPLY, DRIES FAST

PREVENTS CORROSION ON UNDERWATER METALS

COMPATIBLE WITH ALL ANTIFOULING PAINTS

TotalProtect Epoxy Barrier Coat Primer

TotalProtect Epoxy Barrier Coat Primer

PREVENTS OSMOTIC BLISTERS

EASY TO APPLY, DRIES FAST

PREVENTS CORROSION ON UNDERWATER METALS

COMPATIBLE WITH ALL ANTIFOULING PAINTS

Couldn't load pickup availability

Tough, flexible protection from osmotic blistering

A barrier coat seals a fiberglass hull, blocking water entry and inhibiting blister formation in underwater gelcoat and fiberglass. If your boat has a fiberglass hull, you should protect it with a barrier coat beneath your bottom paint. Just 8-12 dry mils of TotalProtect is all it takes to establish an aggressive barrier coat. Water can’t get in to do damage. TotalProtect is also flexible and can take the tough pounding and movement a hull undergoes without cracking or lifting.

Prevents corrosion on all metals above and below the waterline

When we say TotalProtect is a 'universal' primer, we mean it. Besides being an effective, impermeable barrier coating on fiberglass hulls, TotalProtect has great adhesion and corrosion-protection benefits as an epoxy primer on all metal substrates. Use one, two, or three coats depending on your application. It blankets the metal so oxygen can’t reach it and corrosion can’t start — either above the waterline or underwater.

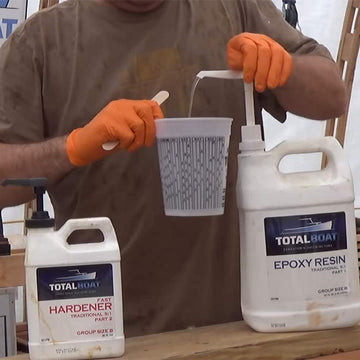

3 to 1 ratio is easy to mix accurately for best results

To prevent waste, mix whatever amount of TotalProtect you think you can use before it kicks, which is 5 hours — a long time compared to competing brands. It’s easy to mix and use, but if you’re new at this, you may want to start with a test batch to hone your technique. Three parts base with one part curing agent in a paint pot will do it. For example, use a graduated cup to measure 12 ounces of base to 4 ounces of hardener. Mix well. Accurate measuring is easy to do, and it’s important because with smaller amounts of base and curing agent, slight deviations in the mix ratio are greatly magnified. It’s just something to be aware, rather than afraid of. Otherwise it’s easy to mix the entire batch at once. Just dump the curing agent into the can of base. We made sure there’s enough room in there. No need to grab a separate container for mixing.

Your thumb will tell you when it’s time to recoat or overcoat

Timing is everything when applying antifouling bottom paint over TotalProtect. Once you’ve laid down the final coat of TotalProtect, the right time to overcoat with antifouling paint is when the surface is thumbprint tacky. That means your thumbprint is visible on the surface, but there’s no epoxy stuck to your thumb. If there’s epoxy on your thumb, it’s too soon. If you can’t see your thumbprint on the surface at all, you’ve missed the overcoat window and need to sand with 80-grit paper or apply another coat of TotalProtect. Wait for thumbprint tackiness, then overcoat with antifouling.

Also use the thumbprint tacky test for recoating TotalProtect on itself. TotalProtect gives you more time between coats as you’re building up the barrier coating. After 60 days, if you miss the overcoat window, sand with 80-grit paper to make the surface toothy enough for the next coat.

Not meant to fill larger surface imperfections

TotalProtect will fill in tiny scratches due to its high-build capabilities, but it’s not a filler. For scratches, dings, and dents 1⁄16” deep or greater, use TotalFair epoxy fairing putty first, then sand smooth and overcoat.

TotalProtect Barrier Coat Primer Details

- Durable, flexible, high-build epoxy primer for above and below the waterline.

- Barrier coat prevents water migration and absorption in fiberglass hulls.

- Compatible with all antifouling paints.

- Bonus: Each Gallon order includes a paint roller frame, 3/16″ nap solvent-safe roller cover, metal tray, 10-in. stir stick, XL paint suit, 2-in. chip brush, a Scotch-Brite™ pad, and 1 roll of 1-in. painter’s tape.

- Fast-drying, two-part epoxy primer features easy 3:1 mix ratio.

- Flows well and dries smoothly and evenly. No tedious sanding required.

- Apply to fiberglass, steel, stainless steel, lead, bronze, and cast iron.

- Provides excellent corrosion protection on underwater metals such as keels, props, shafts, trim tabs, and thru hulls.

- TotalProtect is easy to apply by brushing, rolling, or spraying; if rolling, use a 3/16" roller cover, for best results.

- Thinning: Only use TotalBoat Epoxy Primer Thinner 200 (up to 10%) for thinning, to improve workability and flow.

- Colors: Available in White and Gray

- Size: Quart Kit includes ¾ quart Part A Base and ½ pint Part B Activator

- Size: Gallon Kit includes ¾ gallon Part A Base and 1 quart Part B Activator

Important Safety Information

Wear protective gloves, clothing protection, eye/face protection, and a proper respirator when applying or sanding TotalBoat TotalProtect.

SEE HOW EASY IT IS TO USE TOTALPROTECT

SEE HOW EASY IT IS TO USE TOTALPROTECT

TECHNICAL DATA

- Application Method: Brush, roll (with 3/16″ (recommended) to 3/8″ nap or foam solvent-safe roller cover), spray (airless, conventional, or HVLP)

- Application Temperature/RH: 50-95°F, relative humidity 0-85%

- Number of Coats: 2-3 (minimum), when using a 3/8″ roller cover; 3-4 coats, when using a 1/4″ roller cover; 4-5 coats, when using a 3/16″ roller cover. It’s more important to ensure 8-12 mils dry film thickness than focus on a certain number of coats.

- Film Thickness (per Coat): 4 mils dry (7 mils wet, when using a 3/8" roller cover) 3 mils dry (5.5-6 mils wet, when using a 1/4" roller cover) 2.5 mils dry (4-5 mils wet, when using 3/16" roller cover)

- Dry Time to Recoat with more TotalProtect: 2 hours - 60 days @ 90ºF, 3 hours - 60 days @ 70ºF, 6 hours - 60 days @ 50ºF

- Dry Time to Overcoat with Antifouling Paint: 3-6 hours @ 90ºF, 5-8 hours @ 70ºF, 7-10 hours @ 50ºF

- Dry Time to Launch (Minimum): 12 hours @ 90ºF, 24 hours @ 70ºF, 5 days @ 50ºF

- Recommended Finish Coating: Ablative antifouling paint

- Colors: Gray or White

- Finish: Matte

- Mix Ratio by Volume: 3:1 (3 parts base to 1 part curing agent)

- Theoretical Coverage: 225 square feet per gallon (at 7 mils wet, not accounting for waste)

- VOC Content (g/L): 337 (Part A), 347 (Part B), 340 (Parts A and B Admixed)

- Thinner: Optional - Brush, Roll, or Spray application - TotalBoat Epoxy Primer Thinner 200 (maximum 10%)

- Induction Period: After mixing base and curing agent thoroughly, allow a 15-minute induction period before reduction and application

- Surface Prep Solvents: TotalBoat Dewaxer & Surface Prep (Fiberglass, Wood, Bare Steel, Aluminum); TotalBoat Special Brushing Thinner 100 (Wood)

- Cleanup Solvents: TotalBoat Epoxy Primer Thinner 200 or TotalBoat Dewaxer & Surface Prep

-

TotalProtect Epoxy Barrier Coat Primer

- Best for:

- Primer type:

- Substrates:

- Above/below waterline:

- Suitable topcoats:

- Application methods:

- Number of coats:

- Thinner:

- Cleanup:

- Coverage:

- Application temperature/RH:

- Units of measure:

- THIS ITEM

-

TotalProtect Epoxy Barrier Coat Primer

- Best for: High-build epoxy primer for corrosion protection or osmotic blister prevention

- Primer type: Barrier coat

- Substrates: Wood, fiberglass, metals, and previously painted surfaces in good condition (except for 1-part paints)

- Above/below waterline: Above or below

- Suitable topcoats: Antifouling paints, topside paints, urethanes

- Application methods: Brush: (natural bristle, solvent safe); Roll: (3/16" - 3/8" nap or foam solvent-safe roller cover), or Spray: Conventional, airless, HVLP

- Number of coats: 2-3 coats (minimum), when using a 3/8" roller cover; 3-4 coats, when using a 1/4" roller cover; 4-5 coats, when using a 3/16" roller cover

- Thinner: TotalBoat Epoxy Primer Thinner 200

- Cleanup: TotalBoat Epoxy Primer Thinner 200 or TotalBoat Dewaxer & Surface Prep

- Coverage: 225 sq ft/gal (at 7 mils wet, not accounting for waste)

- Application temperature/RH: 50-90ºF; 0-85% RH

- Units of measure: Quart Kit or Gallon Kit in Gray or White

YOU MAY ALSO LIKE

FREQUENTLY ASKED QUESTIONS

-

What applications is this epoxy barrier coat most appropriate for?

Using TotalProtect is recommended on fiberglass boats as a watertight primer before the application of antifouling bottom paint. It provides excellent corrosion protection on underwater metals such as keels, props, shafts, trim tabs, and thru hulls, and its anti-corrosive properties prevent underwater metals from deteriorating. It is compatible with fiberglass, metals, wood, and previously painted surfaces in good condition (compatible over 2-part paints ONLY). -

What is the difference between TotalProtect Barrier Coat and 2-Part Epoxy Primer?

TotalBoat 2-Part Epoxy Primer is a tie-coat primer that sticks to the substrate and provides good adhesion for the coating applied over it. It comes in surfacing primer, high-build, and clear versions. You would not use it as a barrier coat.

TotalProtect is made specifically to prevent osmotic blistering on fiberglass/gelcoat boats and should be overcoated with antifouling paint. It also requires more coats than a typical tie-coat primer, at a very specific mil thickness, and has a 3:1 mix ratio by volume. -

What paints are compatible with TotalProtect?

All antifouling paints may be applied over TotalProtect. This primer may be used above and below the waterline. Most 1 and 2 part topside finishes are compatible, as well. -

Can I use TotalProtect as a filler?

TotalProtect will fill in tiny scratches due to its high-build capabilities, but it’s not a fairing compound or filler. For scratches, dings, and dents 1/16” deep or greater, use TotalFair epoxy fairing putty first, then sand smooth and overcoat. -

Can you apply gelcoat over this primer?

Yes. Sand cured primer smooth with 220 and wipe down with acetone before gelcoating. -

Can I use TotalProtect on plywood?

Yes. We recommend applying 4-5 coats. -

Can this primer be used above the waterline?

Some customers have used TotalProtect as a topside primer. Be aware that this thick primer does not have the smooth sanding characteristics of an epoxy surfacing primer. It will require a lot of sanding and may not result in as smooth a finish. -

Does TotalProtect need a topcoat?

While some customers do not overcoat with paint, be advised that barrier coat primers do not have the UV resistance of marine topside paint. Some customers have also used TotalProtect as a finish below the waterline for trailered boats. -

Does it matter whether I use gray or white color Totalprotect?

If your boat’s paint or gelcoat is a shade of white, we recommend choosing white. This way, if the top coat gets scratched, it won’t be as noticeable. -

What is the best way to apply TotalProtect?

TotalProtect may be brushed, rolled, or sprayed. We prefer the “roll and tip” method, and recommend a 3/16” nap or foam solvent-resistant roller cover. Thin up to 10% with TotalBoat Epoxy Primer Thinner 200. -

How many coats should I apply?

We recommend applying 2-3 coats at minimum when using a 3/8″ roller cover, 3-4 coats when using a 1/4″ roller cover, and 4-5 coats when using a 3/16″ roller cover. It’s more important to ensure 8-12 mils dry film thickness than focus on a certain number of coats. -

How much barrier coat primer will I need for my boat?

Estimated coverage @ 2 mils dry thickness per coat is 400 sq. ft. per gallon. Your best option is to measure your boat to estimate total square feet you need to cover. One rule of thumb that can be used to estimate the area below the waterline is to take the length, multiply by the beam, then multiply that number by .85. -

What is the typical coverage of TotalProtect?

Sq. ft. per gallon coverage is 225 square feet at 7 mils wet. -

How long does TotalProtect take to dry?

Dry time for TotalProtect can mean a few different things. Dry time to recoat with TotalProtect is 2 hrs at 90ºF, and 6 hrs at 50ºF (up to a max of 60 days). Dry time to overcoat with antifouling paint is 3-6 hours at 90ºF, and 7-10 hours at 50ºF. To launch, it is critical to let TotalProtect dry a minimum of 12 hours at 90ºF, 24 hours at 70ºF, and 5 days at 50ºF.