We invited Steve Denette and Annie B of Acorn to Arabella to the TotalBoat Makerspace, Narwhal Labs, to get some help fiberglassing some important pieces for Arabella. The wooden boat builders and experts (Annie B is a straight-up wooden boat expert and fair to say Steve is now, too!) arrived in search of some pointers and hands-on help learning the dos and don’ts of epoxy and fiberglass work. With some boat parts built by Steve in hand, we glassed and gabbed for 2 days, with Andrew offering up lots of assistance and great tips that helped them out back at home when they had to do some more fiberglassing. The training is important before they take on glassing the house sides which will be much more visible than the pieces they brought to the Lab.

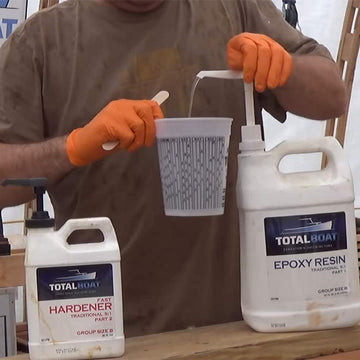

The parts they brought in needed some specific help that the fiberglass was perfect for; the anchor locker, shown above, needed fiberglass and epoxy to be waterproof and take some abuse from anchor chain stowage and use. The shower pan needed a coating of fiberglass that also provides waterproofing and protection from prolonged use but would be buried underneath wooden floorboards for drainage. The most interesting project was the “reefer,” or fridge box, that was built using a wooden plug that Steve built to fit the space needed in the galley counter. We used a 12oz biaxial fiberglass to make several layers, using High Performance Epoxy to wet it out with no blushing, which could then be popped off and freed from the mold. Using packing tape and mold release, it popped perfectly off the plywood plug and was exactly what Steve was hoping for. Back in the boat shop in the third bonus video, released today, Steve and Annie built out the exterior insulation walls uding rigid foam and some of our more dense 6lb Flotation Foam to fill in gaps with its expanding action. The 6lb foam is better for jobs like this where density trumps flotation. Our 2lb foam is the less dense version of this fun product that is better suited for flotation under seats and in small areas below deck and in both cases, as Steve mentions, the force of the expanding, curing foam is enough to not only pop off boat decks, but push through the tiniest of pin holes and find every little gap in its path.

Check out today’s video(s) of the week and see how these projects will transform Arabella and her fridge, anchor locker and shower pan; each being one of the most important pieces to go into the boat for a life well-lived aboard this mobile floating home. Enjoy!