Andrew Nota, the resident “maker” in our TotalBoat Makerspace, Narwhal Labs, is an avid waterman. So, he’s long had a speargun build on his list of things to make – even before he learned to spearfish. But a few quick trips around his hometown in Newport, RI quickly convinced him that not only was it a hobby to behold, but one to embrace with his own designed and built spear gun. Check out the process Andrew followed to build this impressive piece in today’s video of the week.

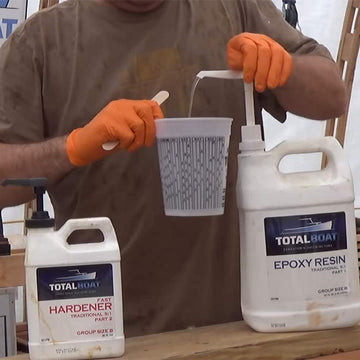

Using African mahogany Andrew designed a 2 piece wooden main piece, epoxied in a thin layer of carbon fiber which he added for strength. Knowing the gun will produce a lot of force, Andrew added the carbon fiber to add rigidity and strength to the gun. He also used the HIgh Performance Epoxy to build himself custom grips with some texture that he created by making himself a resin-printed piece first that he could use as a plug to make a mold. He then filled the mold with white tinted epoxy that could be demolded into the perfect shape. He attached parts and sprayed on Halcyon for the ultimate finish that would protect the piece from abuse and sun and of course, salt. Check out the build and then be sure to check out how the team in the Lab tested the force with which this gun can fire it’s spears – it’s no joke! Jeff, Chief Narwhal, finds this out for himself first hand.