In today’s video of the week, Louis Sauzedde, from Tips from a Shipwright, begins finishing the woodwork for his V-Bottom Skiff build! He shows us how to saw and laminate the lodging knees with our High Performance Epoxy as he shares his tips and tricks along the way!

Lou is getting close to finishing up his wooden boat build and we cannot wait to see it out on the water! In this weeks video, he makes the knees out of white oak laminates that will be over 2 inches thick when all glued up. Using the top figured knee as a pattern, he traces the shape onto the laminates and cuts them out on the band-saw. Then, each layer is held together individually with blue painters tape and he drills holes to coordinate them for when it’s time to re-stack and glue them with epoxy. The drill holes will fit nails in to hold everything together and will be removed once the glue up is finished.

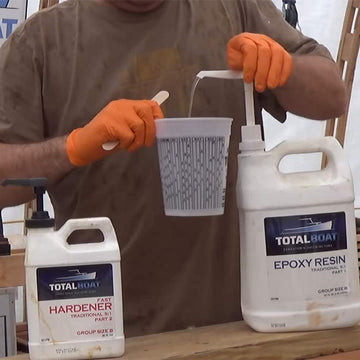

He then mixes our High Performance Epoxy with medium hardener, sharing his tips on pouring an accurate amount directly from the bottles into our mixing cups. Once parts A and B are mixed, he mixes in a generous amount of thickener until it reaches the perfect consistency to prevent sagging and drips. Lou then applies the epoxy to each layer and places the pieces to the nails. He tightly clamps the knees until the epoxy is cured. The next morning, Lou removes the nails and clamps and sands down the excess epoxy with an electric planer, and voila: the knees are done!

The last few things he has to do are to install the lodging knees, inwales and caps. Then all the woodworking for the boat will be finished and ready for some paint! This V-Bottom Skiff is so close to getting it in the water and we cannot wait for splash day! Be sure to give this video a like and subscribe to Lou’s channel for more woodworking and wooden boat building tips! Thanks for watching!