We are back in the shop with our favorite shipwright, Lou Sauzedde, from Tips of a Shipwright. Lou is getting close to finishing up his V-Bottom Skiff Wooden Boat build, and in today’s Video of the Week, he finishes the knees with our High Performance Epoxy and clamps them in place so he can install the inwales.

He is using the epoxy to glue the laminated pieces to complete the knees. He adds thickener to get the epoxy to the right consistency, then spreads it on the surface with a notched trowel for an even and smooth coating. Once he glues the layers of laminate separately, Lou brings them over to the boat clamping them together vertically against the transom and side planking. This allows him to remove the pieces once glued so they can try and be re-installed as one piece.

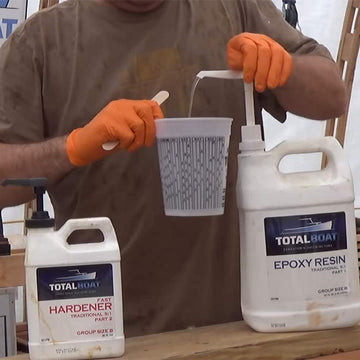

A question Lou gets asked all the time is about the different hardener options for our High Performance Epoxy; which one to use and why? There are different variables when it comes to choosing the correct hardener. It comes in slow, medium and fast. While he uses medium for most of his projects, he has good reasons when needing to work with the other two also. If he is mixing a larger amount and doesn’t want it to set up too quickly, use a larger mixing bucket and the slow hardener for a longer working time. Temperature also plays a determining factor. In the warmer months, Lou sticks with the slow hardener and in the cooler months will go with medium. He does use the fast hardener at times, but typically only for smaller projects he needs to glue up and harden quickly.

Once the glue-ups are dry the following day, Lou is ready to install the knees in place and begins to saw the inwhales down to size to get them in the boat too. It won’t be too much longer until this wooden boat build is finished and ready to launch! Be sure to give this video a like and subscribe to Lou’s channel for more woodworking and wooden boat building tips! Thanks for watching!