CRYSTAL CLEAR RESIN FOR TURNING BLANKS

Turns easily without breaking, chipping or cracking.EASY TO USE, EXTENDED WORKING TIME

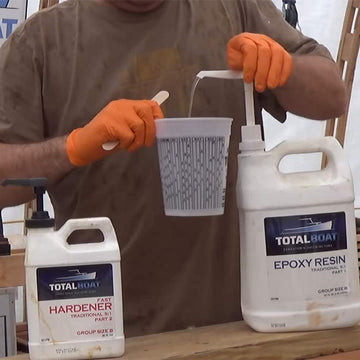

Allows more time for large, complex pours.SIMPLE 1:1 MIX RATIO BY VOLUME

No gram scale needed for accurate measuring.EASY TO TINT, UV RESISTANT

Add pigments for a custom look. Apply a clear coat product for best UV protection.Cast N Turn Clear Urethane Casting and Turning Resin

Cast N Turn Clear Urethane Casting and Turning Resin

CRYSTAL CLEAR RESIN FOR TURNING BLANKS

Turns easily without breaking, chipping or cracking.EASY TO USE, EXTENDED WORKING TIME

Allows more time for large, complex pours.SIMPLE 1:1 MIX RATIO BY VOLUME

No gram scale needed for accurate measuring.EASY TO TINT, UV RESISTANT

Add pigments for a custom look. Apply a clear coat product for best UV protection.Couldn't load pickup availability

Optically clear casting urethane resin that’s easier to measure and easy to turn

Whether you’re an experienced woodturner, you’re just learning about turning, or you’re turning treen and want to add resin to your repertoire so you can try your hand at casting and turning hybrid blanks, Cast N Turn urethane is the clear choice for casting one-of-a-kind turning blanks for pens, bowls, knife scales, coyote howlers (for those times when you need to mess with a coyote’s territorial instincts – hey – you never know!), and more.

Other casting urethane resins are measured by weight ONLY. With Cast N Turn, you don’t need to invest in a digital scale to get the precise ratio and a proper cure. Just measure 1 part Part A and 1 part Part B – by volume . Cured pieces are rigid, high-impact plastic that can handle the heat and pressure of turning on a lathe, without melting, deforming, chipping or cracking. Get 100% bubble-free results, when used with a pressure pot.

Get creative with color and encapsulations

Tint Cast N Turn with a variety of pigments, such as mica powders and dyes. The important thing is to add the colorant to Part A and mix thoroughly before combining Part A with Part B, because once combined, the clock starts ticking to get the resin poured into your mold and put into a pressure pot for curing.

Besides adding color, you can encapsulate objects in the resin such as stabilized tree burls or scraps of worthless wood most would consider fit only for the firepit, casting them into blanks, then turning them into something amazing!

Longer working time gives you more time to cast larger pieces

Cast N Turn’s generous 12-minute working time is longer than that of traditional urethane resin, which takes some of the pressure off of you to get your casting into the pressure pot before the resin starts to set.

Cast N Turn Details

- Ultra clear urethane resin for casting turning blanks.

- Use with a pressure pot for bubble-free results.

- Creates hard, high impact, bubble-free pressure castings.

- Extended working time is ideal for larger or more complex pours and encapsulations.

- Simple 1:1 mix ratio by volume – no gram scale needed.

- Great for encapsulating objects.

- Tint with dyes and colorants such as mica powders.

- Turns easily without cracking, splitting, breaking or chipping.

- Polish to an eye-catching, extremely high-gloss finish.

- Cured pieces resist yellowing when exposed to sunlight.

- Size: Quart Kit (1 Pint Part A and 1 Pint Part B)

SPECIFICATIONS

- Application Method: Casting

- Application Temperature/RH: 65-80ºF (at 0-60% relative humidity)

- Working Time: 12 minutes (3.2 oz. / 100 gram mass)

- Demold Time: 2-4 hours (3.2 oz. / 100 gram mass)

- Full Cure: 5-7 days

- Maximum Pour Depth/Volume: 3" for up to 16 oz. of mixed material; when more Cast N Turn is poured, the maximum depth is 2"

- Color: Crystal clear

- Mix Ratio by Volume: 1:1 (1 part Part A to 1 part Part B)

- Mix Ratio by Weight: 96:100 (96 parts Part A to 100 parts Part B) – To measure by weight, put your measuring cup on the scale and tare the scale to zero before pouring components into cup

- IMPORTANT MIXING NOTE! To avoid the potential for moisture contamination from wooden stir sticks, do not use wooden stir sticks to mix Cast N Turn components. Plastic stir sticks are strongly advised.

- A pressure pot is required to make 100% bubble-free castings

- Food Safe Once Cure: No

- UV Stable Once Cured: Cast N Turn has good UV resistance, but for maximum protection, apply a clear UV urethane coating.

- Shelf Life: Unopened: 1 year. Opened: Hours to days, dependent on the level of moisture contamination. Opened, Bloxygen® Used Before Closing: 3-6 months.

YOU MAY ALSO LIKE

FREQUENTLY ASKED QUESTIONS

-

Is urethane resin better than epoxy for turning applications?

Urethane resins are preferred over epoxy because they cure faster and are ready to machine up to three times faster than epoxy. Urethane resins are also low odor and are optically clearer than epoxy. -

What is a pressure pot?

A pressure pot is a machine that applies air pressure (supplied by an attached air compressor) to resin castings in order to force resin into cracks or inclusions (voids) in wood or into thin sections of a mold. The pressure pot also eliminates air bubbles by pulverizing them so they are too small to detect. A pressure pot has a gauge to help you maintain a safe pressure range while casting – never exceed the pressure rating on your pressure pot. -

Do I need a pressure pot for curing Cast N Turn urethane resin?

It’s important to pressurize a resin casting in order to eliminate bubbles and to force the resin into all the nooks and crannies. To ensure 100% bubble-free castings, a pressure pot is required when using TotalBoat Cast N Turn, however, if you have a small casting, mix the components slowly and pour the mixture slowly into the mold, you’ll create minimal bubbles. -

What pressure pot setting do I use when casting turning blanks with Cast N Turn?

Use a pressure setting of 50psi or greater when curing Cast N Turn in a pressure pot. Never exceed the maxiumum pressure rating on your pressure pot. -

Should I remove air bubbles from Cast N Turn Part A and Part B before mixing them together?

To get rid of air bubbles before combining Part A and Part B, you can measure each component in a separate cup at the specified 1 to mix ratio by volume, then place the cups in a vacuum chamber. Once you combine Parts A and B, you must pour them into a prepared mold and put the mold into a pressure pot to cure. Curing in a pressure pot will also help ensure a bubble-free casting. -

What is the maximum pour depth for TotalBoat Cast N Turn resin?

The maximum pour depth for Cast N Turn urethane is 3″ at 16 oz. of mixed material. If you will be pouring more than 16 oz. of mixed material in a single pour, the maximum pour depth is 2″. -

Is Cast N Turn urethane resin food safe?

No. Cured TotalBoat Cast N Turn urethane resin IS NOT safe for direct or indirect contact with food. -

Is Cast N Turn urethane resin UV resistant?

Yes, Cast N Turn has good UV resistance, but for maximum protection apply a clear coat product. -

What pigments can I use to change the color of Cast N Turn urethane?

Cast N Turn can be tinted with some dyes, mica powders and other types of coloring agents. Do not use any water-based dyes or alcohol ink pigments, or the resin will not cure properly. Always add the desired coloring agent to the Part A component and mix thoroughly before mixing Part A and Part B. To ensure that you achieve your desired effect, do a test sample casting with any colorants before using them in your final project to determine how the colorants will react with Cast N Turn. -

What is a turning blank?

A turning blank is a stock of material that’s been prepared and sized to produce a particular object on a wood turning lathe. The blank is fastened to the chuck on the lathe and rotated against a tool to form an object such as a bowl or vase, for example. Wood turning blanks are made of stabilized wood; hybrid turning blanks are made of wood and resin. -

What is a knife scale?

A knife has a blade and a handle. The scales are the two pieces of material on either side of the knife handle. Knife scales can be made from a number of different materials, including epoxy resin, urethane resin, and wood. -

Do I need to stabilize wood before encapsulating it in Cast N Turn urethane?

Not all woods need to be stabilized, but any piece of wood that’s soft, spongy, spalted or punky, such as porous scrap wood or tree burls should be stabilized with resin before encapsulating in Cast N Turn in order to prevent bubbles during the cure. Stabilizing wood means using vacuum pressure to remove the air in the wood and replace it with a stabilizing resin such as CA or Cactus Juice. Encapsulating unstabilized wood can result in excessive air bubbles, improper cure, weak wood breaking apart when it’s turned, or holes in the wood getting filled with tinted resin.