ULTRA-CLEAR EPOXY PREFERRED BY MAKERS

Crystal-clear, scratch-resistant finish looks like glass.EASY TO USE, EASY TO TINT

Simple 1:1 mix ratio by volume. Tint with epoxy-safe mica powders and other pigments.LONG WORKING TIME

Great for large or complex pours such as river tables.LOW ODOR, LOW VOCs

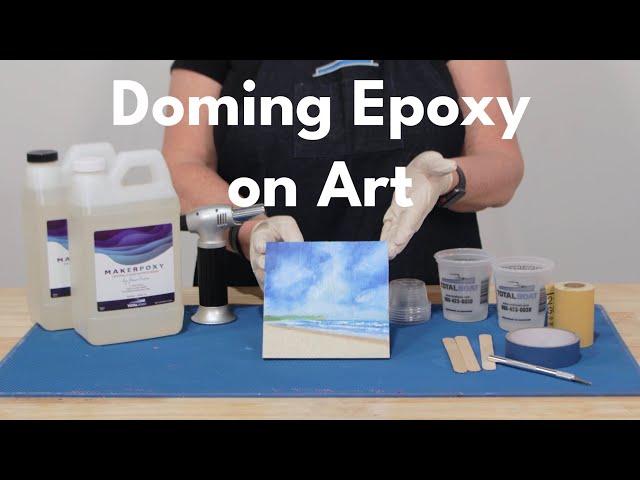

Great for shop or indoor use.MakerPoxy Crystal Clear Artist’s Resin by Jess Crow

MakerPoxy Crystal Clear Artist’s Resin by Jess Crow

ULTRA-CLEAR EPOXY PREFERRED BY MAKERS

Crystal-clear, scratch-resistant finish looks like glass.EASY TO USE, EASY TO TINT

Simple 1:1 mix ratio by volume. Tint with epoxy-safe mica powders and other pigments.LONG WORKING TIME

Great for large or complex pours such as river tables.LOW ODOR, LOW VOCs

Great for shop or indoor use.Couldn't load pickup availability

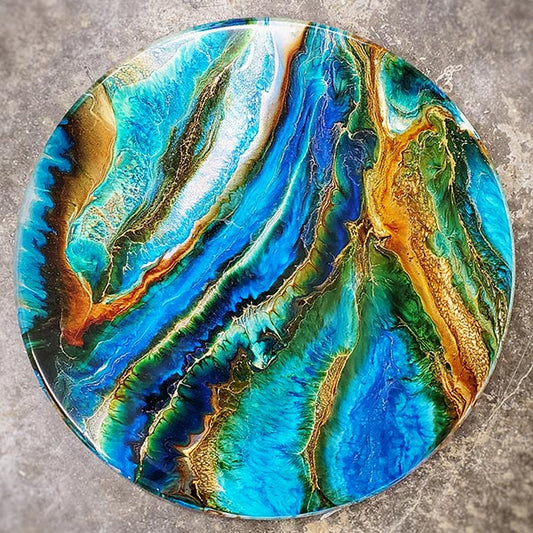

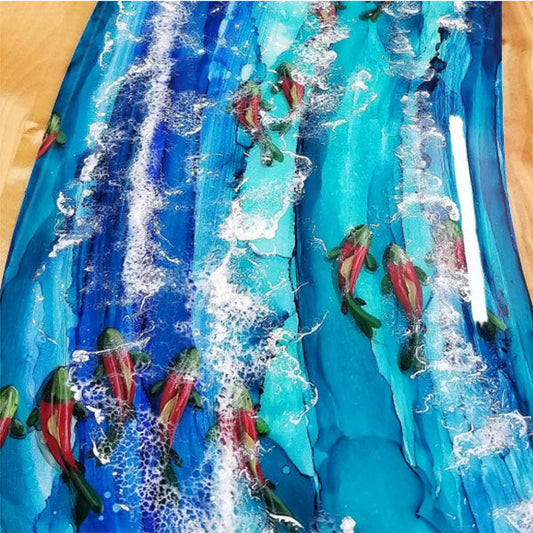

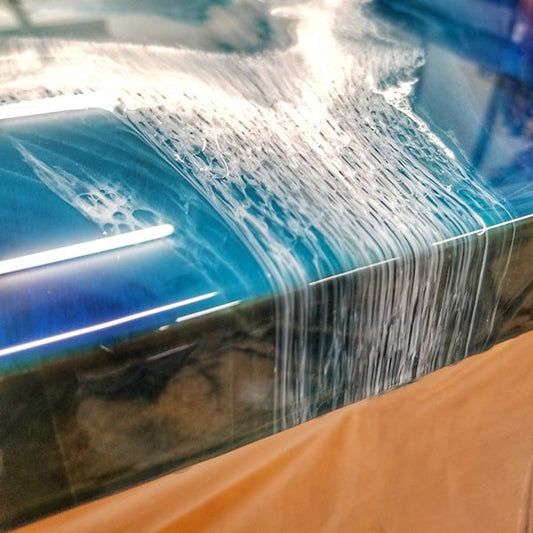

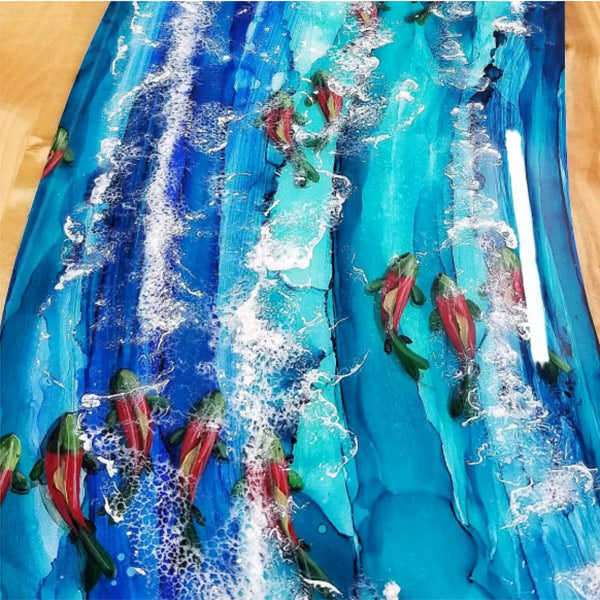

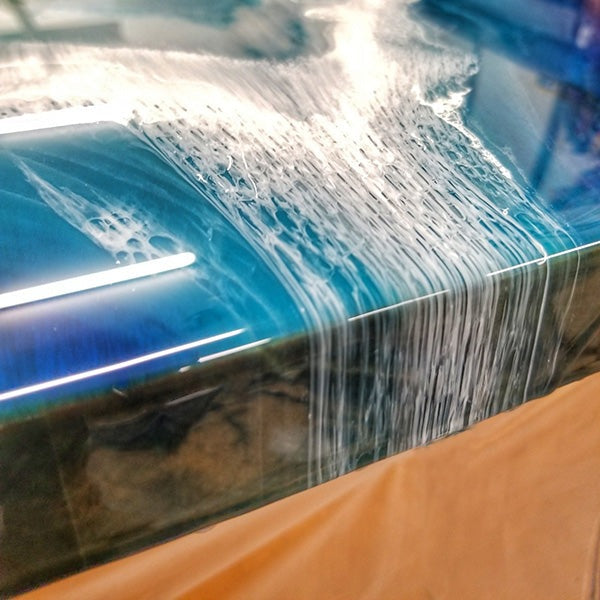

Jess Crow’s epoxy work is a stunning mix of her artistic capabilities, woodworking skills, and her incredibly creative use of epoxy. She’s mastered a water-simulating technique that creates the look of ocean waves splashing on top of her pieces.

Jess’s innovative ocean wave resin technique is currently in the resin art spotlight, and she is continuously pioneering new processes involving epoxy and functional art.

“I often get asked “How do you do that?” and told “I’m not at your level, and won’t ever be.” Ah, my friends…that is not correct. I am learning every single day. I draw. I chip away at wood with crazy ideas. I save every single scrap and utilize it – feel it, cut it up, burn it, and mostly ‘waste it’. Yes, WASTE. I am not afraid to have a project not work out, because honestly it never doesn’t work out: I learn from every single one and therefore nothing is wasted.”

“I often get asked “How do you do that?” and told “I’m not at your level, and won’t ever be.” Ah, my friends…that is not correct. I am learning every single day. I draw. I chip away at wood with crazy ideas. I save every single scrap and utilize it – feel it, cut it up, burn it, and mostly ‘waste it’. Yes, WASTE. I am not afraid to have a project not work out, because honestly it never doesn’t work out: I learn from every single one and therefore nothing is wasted.”

As a maker extraordinaire, Jess excels at thinking outside the box (what box?) and enjoys bringing her ideas to the forefront of the woodworking and art communities, with a strong emphasis on sharing and teaching.

Jess’s work is a testament to the performance and ease of use of our TotalBoat epoxy line. Her work makes our epoxy even better and we are so excited to partner with her to create MakerPoxy Crystal Clear Artist’s Resin by Jess Crow.

MakerPoxy is made for makers! This glossy, ultra clear, scratch-resistant epoxy art resin system ideal for clear coating, shallow pours, embedding, and most art projects. This versatile, UV-resistant, non-yellowing epoxy coating can be used for a wide variety of creations, including wall art, dining tables, coffee tables, bedside tables, headboards, bar tops, and counter tops.

MakerPoxy Epoxy Details

- 100% solids, high-build, high-gloss, pourable epoxy

- Glass-like, crystal clear, scratch-resistant finish

- Can be tinted with concentrated liquid pigments, opaque pigments, alcohol inks, and mica powder pigments.

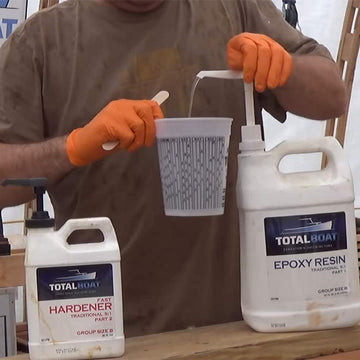

- Simple 1:1 mix ratio by volume

- Extended working time is ideal for larger pours – up to 60 minutes at 77°F.

- Self-levels as it cures.

- Apply to properly prepared wood, metal, stone, ceramic, and concrete surfaces.

- UV-resistant formula protects against yellowing and fading.

- Low-VOC, low-odor formula is great for indoor use.

- BPA-free formula is ideal for finished projects with potential food contact.

- Made in the USA.

- MakerPoxy Metering Pump now available, perfect for dispensing just the right ratio – whether you need a little, or a lot!

- Kit Sizes: Available in four sizes – 8 oz. Kit (4 oz. MakerPoxy Epoxy Resin Part A, and 4 oz. MakerPoxy Epoxy Hardener Part B), 1 Pint Kit (8 oz. MakerPoxy Epoxy Resin Part A, and 8 oz. MakerPoxy Epoxy Hardener Part B), 1 Quart Kit (1-Pint MakerPoxy Epoxy Resin Part A, and 1-Pint MakerPoxy Epoxy Hardener Part B). and 1 Gallon Kit (½-Gallon MakerPoxy Epoxy Resin Part A, and ½-Gallon MakerPoxy Epoxy Hardener Part B)

- BONUS! Each Quart Kit or Gallon Kit order includes: (10) stir sticks, (10) 50mL disposable plastic beakers, and (5) 8 oz. plastic mixing cups. NOTE: The 8 oz. Kit and the 1 Pint Kit contain resin and hardener only.

Not sure how much MakerPoxy you need? Try our simple epoxy calculator to determine how much resin your project will require.

TECHNICAL DATA

- Substrates: Apply to properly prepared wood, metal, stone, ceramic and concrete surfaces.

- Application Temperature: Apply only in temperatures between 70-80°F. Warm conditions are critical for success.

- Colorants and Dyes: Epoxy dyes, colorants, or special effects additives can be added and mixed in. Only use products designed for epoxy.

- Seal Coat Application: Brush

- Flood Coat Application: Pour and spread with an epoxy spreader.

- Maximum Pour Depth per Layer (Flood Coat Applications): 1/8"-1/4"

- Working Time: 60 minutes @ 77°F

- Tack-Free Time: 4-6 hours @ 77°F

- Time to Sand (Optional): 8-10 hours @ 77°F

- Full Cure: 5-7 days

- UV-resistant formula is not intended for outdoor applications with prolonged exposure to sunlight. For superior UV protection, durability, and clarity, overcoat cured MakerPoxy with TotalBoat Halcyon Clear Rugged Gloss Varnish

- Do not place items hotter than 110°F on the cured surface, or it will become distorted and discolor.

- Color: Clear

- Mix Ratio by Volume: 1A:1B (1 part epoxy resin to 1 part hardener)

- Coverage for 1-Gallon Kit of Mixed MakerPoxy: Roughly 12 square feet @ 1/8"; 6 square feet @ 1/4"

- Volumetric Yield: 25.0 in³/lb per gallon of mixed product

- UV Stable: MakerPoxy has added UV protection to help resist hazing and yellowing from UV exposure. For applications that may be exposed to UV light, we recommend increasing the UV resistance by applying a clear varnish or urethane coating that has UV protection.

- Hardness: 82 Shore D

- Thinner: Do not thin this product.

- Cleanup: Scrape up and remove any uncured material, as needed. Denatured alcohol, lacquer thinner, or acetone may be used to clean up uncured epoxy. Cured epoxy must be removed mechanically.

-

MakerPoxy Crystal Clear Artist’s Resin by Jess Crow

- Best for:

- Cured color:

- Mix ratio by volume:

- Mix ratio by weight:

- Maximum pour depth per layer:

- Application temperature/RH:

- Working time:

- Full cure time:

- BPA free?

- UV resistant?

- Units of measure:

- THIS ITEM

-

MakerPoxy Crystal Clear Artist’s Resin by Jess Crow

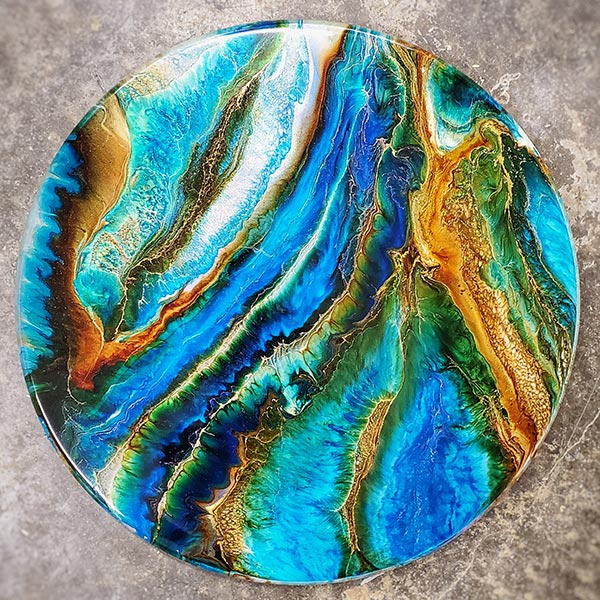

- Best for: Jewelry, coasters, geode art, coating bars and table tops, and ocean wave effect serving boards

- Cured color: Clear

- Mix ratio by volume: 1A:1B

- Mix ratio by weight: 100A:84B

- Maximum pour depth per layer: 1/8" - 1/4"

- Application temperature/RH: 70°F to 80°F

- Working time: 60 minutes @ 77°F

- Full cure time: 5-7 days

- BPA free? Yes

- UV resistant? Yes. For superior UV protection, coat with UV-blocking varnish.

- Units of measure: 8 oz. Kit, Pint Kit, Quart Kit, Gallon Kit

YOU MAY ALSO LIKE

FREQUENTLY ASKED QUESTIONS

-

Is MakerPoxy Art Resin UV resistant?

Yes. The UV-resistant formula protects against yellowing and fading! For even better UV protection, durability, and clarity, overcoat cured MakerPoxy with TotalBoat Halcyon Clear Rugged Gloss Varnish. -

Can I place hot items on the cured surface?

Yes, but do not place items hotter than 110°F on the cured surface, or it will become distorted and discolored. This is standard practice for nearly all epoxies cured at room temperature. -

Can I thin MakerPoxy?

No, thinning epoxy changes the mix ratio and will result in improper cure. -

Is this epoxy safe for food contact?

Yes, MakerPoxy Art Resin BPA-free formula is a safer alternative for finished projects that may come into contact with food. -

What is the coverage of MakerPoxy?

The coverage for a one-gallon kit of MakerPoxy is roughly 12 sq. ft. at ⅛”, and 6 sq. ft. at ¼.″ -

How long will it take to cure?

It will take approximately 5-7 days at 77°F to fully cure. -

Can I use dyes or pigments with MakerPoxy?

Yes. MakerPoxy Artist Resin can be tinted with epoxy-safe dyes, colorants, alcohol inks, mica powder pigments, or special effects additives. -

How long is the working time?

MakerPoxy has a long working time of up to approximately 60 minutes, which is perfect for first-time resin users. However, it’s strongly recommended to mix only as much as you can apply in 20 minutes. -

Can I mix MakerPoxy by weight or volume?

Yes. The mix ratio by volume is 1:1 (1 part A resin to 1 part B hardener) if you mix in a mixing cup by the graduations. The mix ratio by weight is 100A:84B, or 100 units of Part A resin for every 84 units of part B hardener. -

What is the ideal temperature range when working with this resin?

The ideal temperature is around 70°F – 80°F. Warm conditions are critical for a successful cure, and to achieve the best clarity and surface finish.