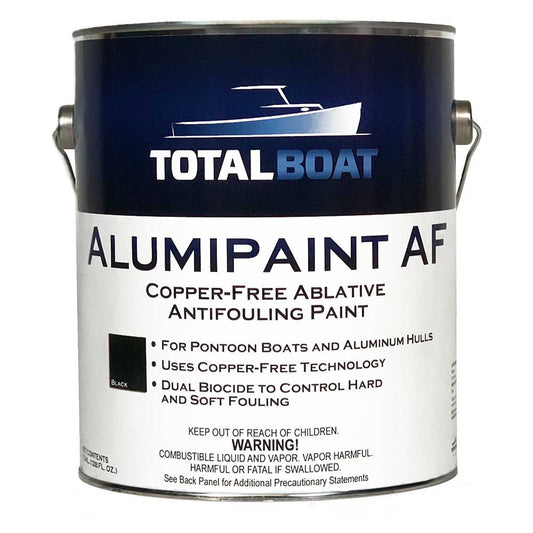

COPPER-FREE ANTIFOULING PAINT FOR ALUMINUM BOATS

Keeps barnacles and slime from clinging to aluminum hulls.FULL-SEASON, SELF-POLISHING FORMULA

Wears away gradually. Prevents paint buildup.WON'T CAUSE GALVANIC CORROSION

Safe for aluminum and underwater metals. Works in salt water and fresh water.EASY TO APPLY - BRUSH, ROLL OR SPRAY

For prepared aluminum, steel and iron boats, aluminum pontoons & underwater metals.AlumiPaint AF Aluminum Antifouling Paint

AlumiPaint AF Aluminum Antifouling Paint

COPPER-FREE ANTIFOULING PAINT FOR ALUMINUM BOATS

Keeps barnacles and slime from clinging to aluminum hulls.FULL-SEASON, SELF-POLISHING FORMULA

Wears away gradually. Prevents paint buildup.WON'T CAUSE GALVANIC CORROSION

Safe for aluminum and underwater metals. Works in salt water and fresh water.EASY TO APPLY - BRUSH, ROLL OR SPRAY

For prepared aluminum, steel and iron boats, aluminum pontoons & underwater metals.Couldn't load pickup availability

Copper-free antifouling paint that's a must for aluminum bottoms and better for the environment

Conventional copper-based bottom paints will eat through an aluminum hull. Because there’s no copper in AlumiPaint AF, it won’t cause galvanic corrosion, so it’s great for painting pontoons, aluminum hulls, and underwater metals like running gear and outdrives. Also, copper is heavy. But an AlumiPaint AF coating weighs less and doesn’t make your engine work as hard, which lowers your fuel bill. No copper and low VOCs also mean it won’t cause harm to delicate marine ecosystems.

If your boat sits idle for a time, AlumiPaint AF doesn’t need scuffing to reactivate its antifouling protection before launching. When you’re ready to go, just hop in, let the good times roll, and don’t worry about any bottom-hugging, slimy, crusty things.

AlumiPaint AF Details

- High-solids, eco-friendly formula provides outstanding, single-season protection against mussels, barnacles, and slime in saltwater, fresh water, and brackish water.

- Each gallon order includes a free roller & metal tray kit, paint suit, and two 14″ wooden stir sticks.

- High-performance, copolymer ablative formula self-polishes by design to stay smooth, prevent paint buildup, and eliminate sanding.

- Copper-free bottom paint won’t cause galvanic corrosion.

- For properly prepared aluminum, iron, and steel boats, aluminum pontoons, and underwater metals. Can be applied to most previously painted surfaces in good condition, including those containing copper-based paint.

- Haul and relaunch without decreasing the effectiveness of the AlumiPaint AF coating.

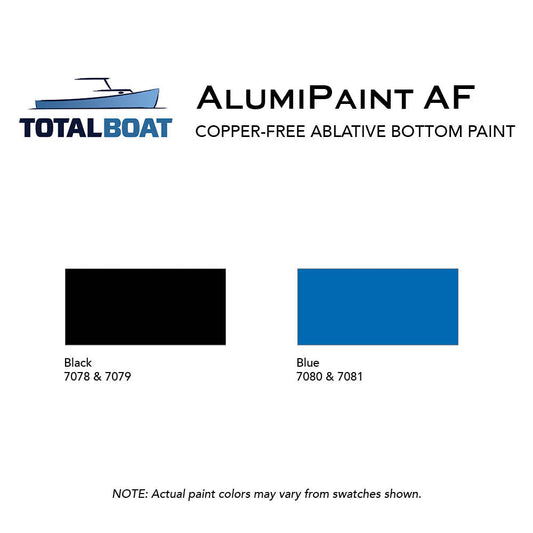

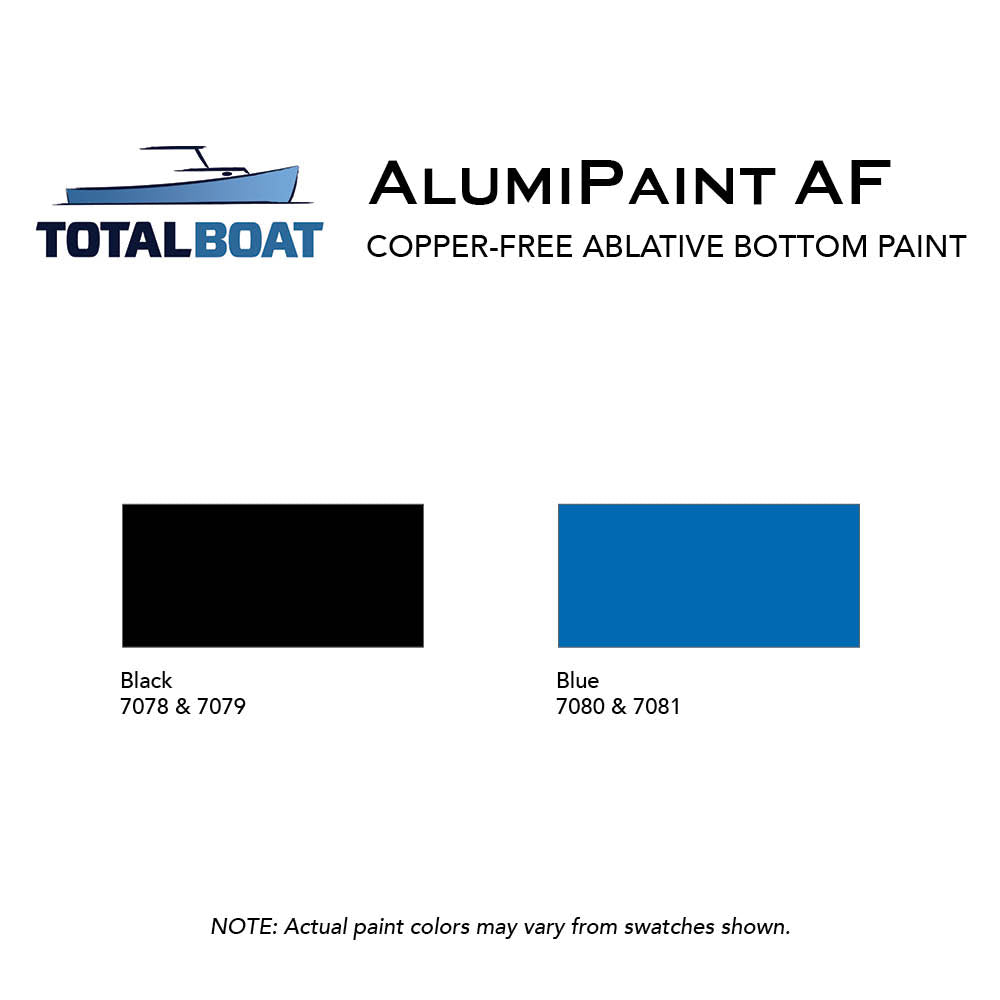

- Colors: Black and Blue

- Sizes: Quart and Gallon

TECHNICAL DATA

- Priming Note: For optimum performance and corrosion prevention, it’s imperative to prep and prime bare aluminum, iron, and steel before applying AlumiPaint AF. For aluminum, we recommend TotalBoat Aluminum Boat Barrier Coat. For iron and steel, we recommend TotalBoat TotalProtect Barrier Coat Primer

- Application Method: Brush, Roll, or Spray

- Application Temperature/RH: 50-90ºF (at 0-90% relative humidity)

- Brushes / Roller Covers: Only use solvent-safe brushes and roller covers to apply AlumiPaint AF. Only use 3/16" foam or nap roller covers.

- Number of Coats: 1-2 per season, for best results

- Film Thickness (per Coat): 1.5 mils dry (2.7 mils wet)

- Dry Time to Overcoat: 1 hour @ 90ºF, 2 hours @ 70º, 4 hours @ 50ºF

- Dry Time to Launch: 2 hours @ 90ºF, 4 hours @ 70ºF, 8 hours @ 50ºF

- Colors: Black, Blue

- Finish: Eggshell

- Seasonal Protection: Single

- Applicable Waters: Salt water & fresh water

- Launch Window: There is no maximum dry time before launching

- Storage: Keep from freezing!

- Biocides: Zinc Pyrithione: 4.8% Tralopyril: 6.0%

- VOC Content: Less than 330 g/L

- Coverage: 500 square feet per gallon (125 square feet per quart)

- Primer: TotalBoat Aluminum Boat Barrier Coat (aluminum); TotalBoat TotalProtect Barrier Coat Primer (steel and iron)

- Thinner: Product should not require thinning. But for brush/roller applications: Thin 5-10% (6-12 oz. per gallon) with TotalBoat Special Brushing Thinner 100; For spray applications: Thin up to 5% (6 oz. of thinner per gallon) with TotalBoat Spray Thinner 101

- Surface Prep Solvent: TotalBoat Special Brushing Thinner 100 or TotalBoat Spray Thinner 100 or TotalBoat Dewaxer & Surface Prep

- Cleanup Solvent: TotalBoat Special Brushing Thinner 100 or TotalBoat Spray Thinner 100 or TotalBoat Dewaxer & Surface Prep

-

AlumiPaint AF Aluminum Antifouling Paint

- Substrates:

- Seasonal protection:

- Applicable waters:

- Colors available:

- Water or solvent based?

- Biocide:

- Application methods:

- Number of coats:

- Primer:

- Thinner:

- Cleanup:

- Coverage:

- Application temperature/RH:

- Units of measure:

- THIS ITEM

-

AlumiPaint AF Aluminum Antifouling Paint

- Substrates: Aluminum, steel/iron, and properly prepared previously painted substrates

- Seasonal protection: Single

- Applicable waters: Salt water & fresh water

- Colors available: Black, Blue

- Water or solvent based? Solvent

- Biocide: Zinc Pyrithione: 4.8% and Tralopyril: 6.0%

- Application methods: Brush, Roll, or Spray

- Number of coats: 1-2

- Primer: TotalBoat TotalProtect or TotalBoat Aluminum Boat Barrier Coat

- Thinner: TotalBoat Special Brushing Thinner 100, for brushing and rolling applications; TotalBoat Spray Thinner 101, for spraying and cool weather brushing/rolling applications

- Cleanup: TotalBoat Dewaxer & Surface Prep or TotalBoat Special Brushing Thinner 100 or TotalBoat Spray Thinner 101

- Coverage: 500 sq ft/gal, 125 sq ft/qt

- Application temperature/RH: 50-90ºF; 0-90% RH

- Units of measure: Gallons and Quarts

YOU MAY ALSO LIKE

FREQUENTLY ASKED QUESTIONS

-

What applications is AlumiPaint AF Copper-Free Bottom Paint most appropriate for?

AlumiPaint AF is an antifouling paint specifically intended for use on aluminum, iron, and steel boats, aluminum pontoons, and underwater metals for protection against mussels, barnacles, and slime in saltwater, freshwater, and brackish water. It can be applied over most previously painted surfaces in good condition, including copper-based paint. -

What is the difference between Alumipaint AF and TotalBoat Krypton?

Alumipaint AF is formulated for maximum adhesion to aluminum and galvanized metals, while Krypton is a copper-free antifouling paint formulated for compatibility with a wide range of substrates like wood and fiberglass. -

Can AlumiPaint AF Copper-Free Bottom Paint be applied above the waterline?

No. This is an ablative bottom paint is designed to prevent growth. It does not contain any UV protection, and should only be used for its intended purpose. -

Do I need to prime before applying Aluminum Antifouling Paint?

If painting over bare metal, yes. For optimum performance and corrosion prevention, it’s important to prep and prime bare aluminum, iron, and steel before applying AlumiPaint AF. For aluminum, we recommend TotalBoat Aluminum Boat Barrier Coat. For iron and steel, we recommend TotalBoat TotalProtect Barrier Coat Primer. This paint is compatible with most marine primers, but always be sure to sand with 80 grit and remove sanding residue prior to painting. -

What is the best way to apply AlumiPaint AF Antifouling Paint?

Shake or stir well to ensure all solids are mixed properly. Paint can be applied by brush, roller, or spray. Important: A 3/16″ nap or foam solvent-safe roller cover is recommended for best results. Before launching, allow drying for the specified time based upon temperature. There is no maximum amount of time that the boat can be launched after painting. -

Can you thin antifouling paint?

AlumiPaint AF should not require thinning most of the time, but you can thin up to 10% (12 oz. per gallon). For brush or roller applications, use TotalBoat Special Brushing Thinner 100. For spray applications use TotalBoat Spray Thinner 101 (up to 5%). -

What is the coverage of this paint?

The typical coverage is 500 sq. ft. per gallon (125 sq. ft. per quart). Remember to use a 3/16″ roller. -

How many coats should I apply?

We recommend applying 1-2 coats per season for the best results. An extra 1-2 coats are recommended over bare substrates, at the waterline, and other areas with increased wear, such as leading edges of rudders, skegs, or struts. -

How long does AlumiPaint AF take to dry?

Dry time to overcoat is 1 hour at 90ºF, 2 hours at 70ºF, or 4 hours at 50ºF. The dry time to launch is 2 hours at 90ºF, 4 hours at 70ºF, or 8 hours at 50ºF. -

How do I maximize the antifouling performance of this paint?

Check the bottom of the boat regularly to make sure it is clean and that no growth is accumulating. The self-cleaning nature of ablative paints is most effective when the boat is used periodically. Boats painted with AlumiPaint AF should not be scrubbed or cleaned for the first six months in the water, and at intervals of not less than three months thereafter.